You are here: Home >> Product center

Detail display

P-35PHN

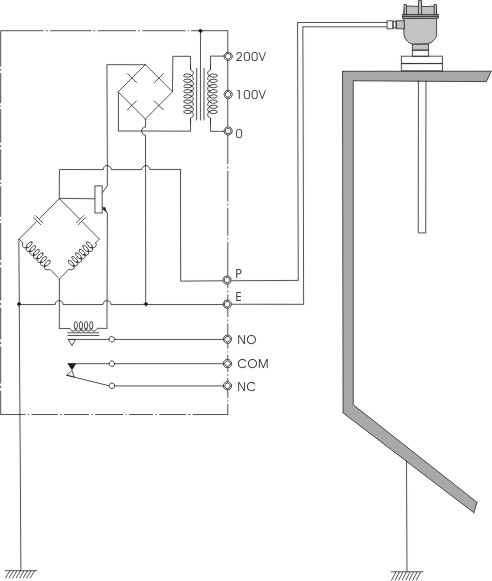

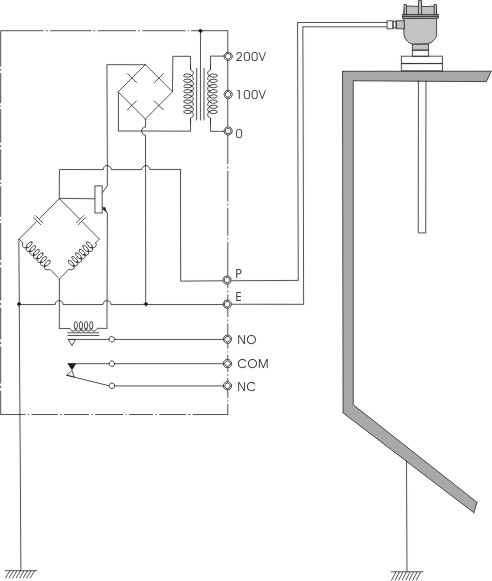

the measuring probe is mounted on the wall of the hopper, the probe and the peripheral wall of silo relative to form a capacitance field. On the material level changes caused by reducing the capacitance. When the feed position reaches the probe position, the capacitance is the maximum, and the relay action in the detection circuit, the output of a switch signal.

Details

Technical index:

Use range: coke, liquid, powder, ash

Probe operating temperature: 300C

Power supply: 50/60Hz 110/220AC

Output: 250V 10A IC AC contact

Delay: 1 to 5 seconds, 1 to 4 points

Connecting cable: 10M

Protection: IP67

1 There is no mechanical moving parts,so long life, maintenance and inspection are easy to carry out.

2 The optimal regulation of sensitivity can be achieved by using a simple scale operation.

3 In order to prevent the impact of the surrounding environment, the machine has become a waterproof sealing structure.

4 Inside a unique electrostatic removal circuit. Electronic circuits are protected by the electrical charge of the measurement.

5 The influence of the main part of the electrode to the dust, water droplets and other attachments can be suppressed to the minimum, and can be measured for a long time.

6 High mechanical strength.

7 Can also be used for high temperature and high pressure measurement.

8 It is very suitable for detecting the concentration of hydrogen ion and the strength of the change.

9 Liquid contact part adopts acid resistant, alkali resistant properties, so it has good corrosion resistance.

10. With the help of the delay circuit (choice) can prevention due to wave, sharp changes in the position of the droplet are caused by a fault and can be handled correctly.

11 Electronic timer, 1 to 5 seconds, 1 to 4 points (button changes) and other different types of use.

principle

The following figure, the measuring probe is mounted on the wall of the hopper, the probe and the peripheral wall of silo relative to form a capacitance field. On the material level changes caused by reducing the capacitance. When the feed position reaches the probe position, the capacitance is the maximum, and the relay action in the detection circuit, the output of a switch signal.

Installation notes

Probe position should energizer away from outlet, to avoid the impact of materials on the probe

The distance between the probe and the controller is within the 10m.

Probe allows down tilt mounting

When the same hopper is installed in several electrodes, in order to avoid the electrode surface sticky stuff, as well as the contact between the electrodes, as far as possible to pull apart

Use range: coke, liquid, powder, ash

Probe operating temperature: 300C

Power supply: 50/60Hz 110/220AC

Output: 250V 10A IC AC contact

Delay: 1 to 5 seconds, 1 to 4 points

Connecting cable: 10M

Protection: IP67

1 There is no mechanical moving parts,so long life, maintenance and inspection are easy to carry out.

2 The optimal regulation of sensitivity can be achieved by using a simple scale operation.

3 In order to prevent the impact of the surrounding environment, the machine has become a waterproof sealing structure.

4 Inside a unique electrostatic removal circuit. Electronic circuits are protected by the electrical charge of the measurement.

5 The influence of the main part of the electrode to the dust, water droplets and other attachments can be suppressed to the minimum, and can be measured for a long time.

6 High mechanical strength.

7 Can also be used for high temperature and high pressure measurement.

8 It is very suitable for detecting the concentration of hydrogen ion and the strength of the change.

9 Liquid contact part adopts acid resistant, alkali resistant properties, so it has good corrosion resistance.

10. With the help of the delay circuit (choice) can prevention due to wave, sharp changes in the position of the droplet are caused by a fault and can be handled correctly.

11 Electronic timer, 1 to 5 seconds, 1 to 4 points (button changes) and other different types of use.

principle

The following figure, the measuring probe is mounted on the wall of the hopper, the probe and the peripheral wall of silo relative to form a capacitance field. On the material level changes caused by reducing the capacitance. When the feed position reaches the probe position, the capacitance is the maximum, and the relay action in the detection circuit, the output of a switch signal.

Installation notes

Probe position should energizer away from outlet, to avoid the impact of materials on the probe

The distance between the probe and the controller is within the 10m.

Probe allows down tilt mounting

When the same hopper is installed in several electrodes, in order to avoid the electrode surface sticky stuff, as well as the contact between the electrodes, as far as possible to pull apart