News show

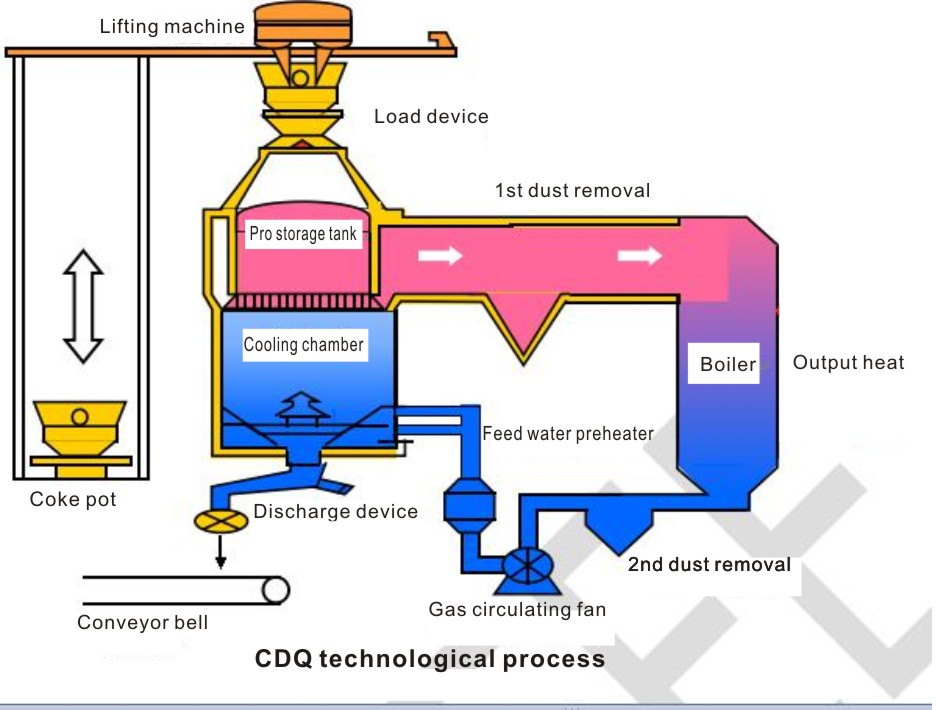

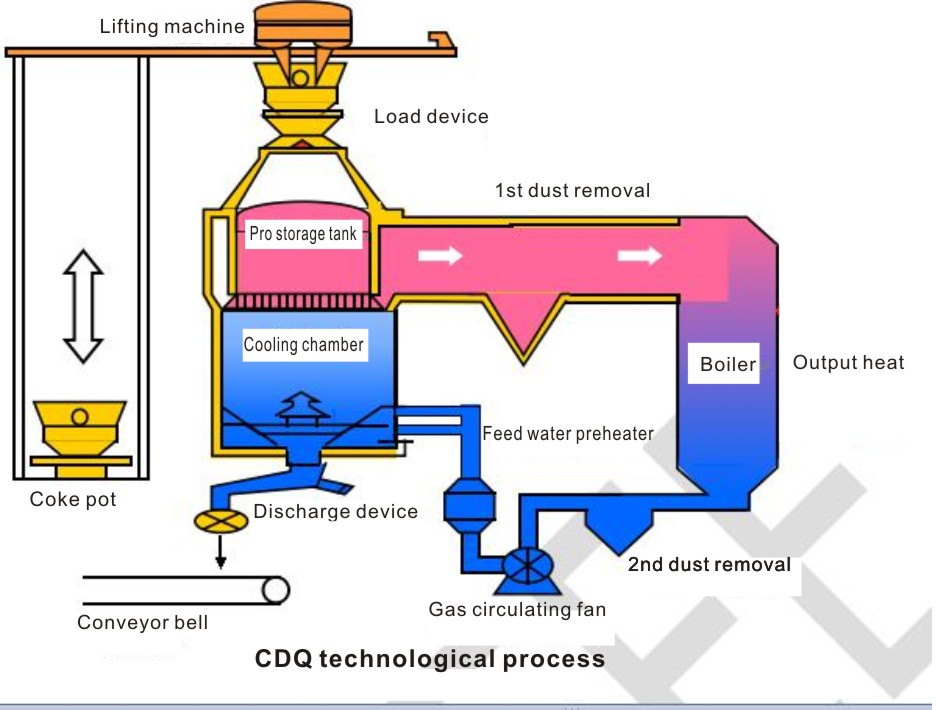

Dry coke quenching (CDQ) is an alternative to wet quenching technology, which is one of the important energy saving and environmental protection technology for the iron and Steel coking process. CDQ technology is using an inert gas for heat exchange medium, in dry quenching oven and red coke do reverse movement of heat exchange, and the coke from 1000 DEG C, cooling to below the temperature of 250 DEG. At the same time, the absorption of the red coke heat of high temperature inert gas to pass CDQ boiler heat to generate steam and drive a steam turbine for power generation; cooling of inert gas in the role of circulating fan was sent back to CDQ cycle, to achieve the purpose of continuous quenching.

Compared to the wet quenching, the dry quenching coke is a kind of coke quenching method using inert gas to cool the red coke. In the coke quenching process, the red coke Conggan quenching furnace top loading, low temperature inert gas by circulating fan drum into the coke dry quenching furnace cooling section of red coke layer, absorption of red coke sensible heat, cooling after the coke from the coke dry quenching furnace bottom discharge, from CDQ annular flue out high temperature inert gas flows through the CDQ boiler heat exchange, produce medium or high pressure steam can be used for power generation or reducing temperature and pressure after the grid using.

Compared to the wet quenching, the dry quenching coke is a kind of coke quenching method using inert gas to cool the red coke. In the coke quenching process, the red coke Conggan quenching furnace top loading, low temperature inert gas by circulating fan drum into the coke dry quenching furnace cooling section of red coke layer, absorption of red coke sensible heat, cooling after the coke from the coke dry quenching furnace bottom discharge, from CDQ annular flue out high temperature inert gas flows through the CDQ boiler heat exchange, produce medium or high pressure steam can be used for power generation or reducing temperature and pressure after the grid using.

CDQ system process: red quenching furnace top loading, low temperature inert gas from circulating fan drum into the coke dry quenching furnace cooling section of red coke layer, absorption of red coke sensible heat and cooling of coke from the coke dry quenching furnace bottom discharge, from CDQ annular flue out high temperature inert gas flow the CDQ boiler heat exchange, the boiler to generate steam for power generation. After cooling of the inert gas by the circulation fan to re drum into the dry quenching furnace recycling. Coke dry quenching (CDQ) by dry quenching furnace, loader, row focal device and hoist, motor vehicles and coke tank, coke tank, a filter, secondary filter, CDQ boiler unit, circulating fan, dust ground unit, circulating water unit, automatic control unit, power generation and other parts of the group.

CDQ system process: red quenching furnace top loading, low temperature inert gas from circulating fan drum into the coke dry quenching furnace cooling section of red coke layer, absorption of red coke sensible heat and cooling of coke from the coke dry quenching furnace bottom discharge, from CDQ annular flue out high temperature inert gas flow the CDQ boiler heat exchange, the boiler to generate steam for power generation. After cooling of the inert gas by the circulation fan to re drum into the dry quenching furnace recycling. Coke dry quenching (CDQ) by dry quenching furnace, loader, row focal device and hoist, motor vehicles and coke tank, coke tank, a filter, secondary filter, CDQ boiler unit, circulating fan, dust ground unit, circulating water unit, automatic control unit, power generation and other parts of the group.